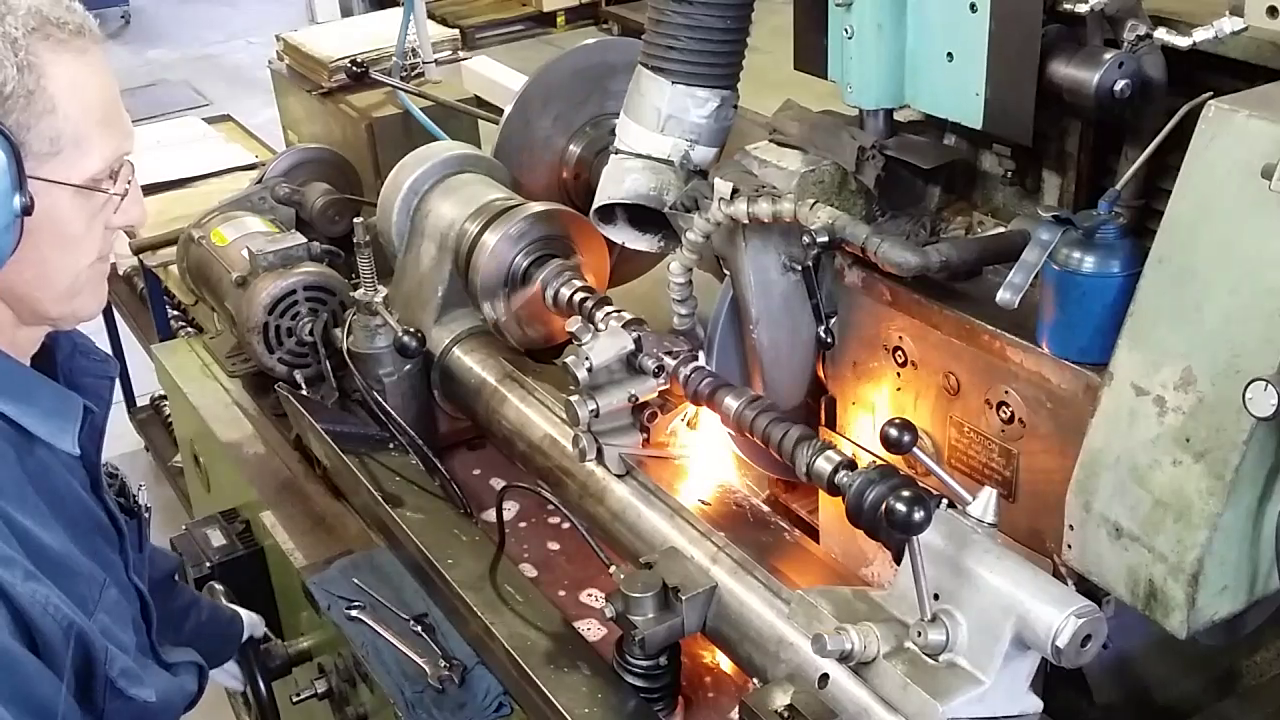

After grinding several cams which may be used in our Project Holden EFI V8 engine we pulled the stock cam out. After cleaning old gaskets and preparing the new cam, we installed the new cam, and new timing set. New lifters were fitted along with some LT-1 valve springs to increase spring pressures to handle the extra valve lift, duration and aggressiveness of the lobe design. Lifter pre-load was set and reassembly begins so we can move to install the engine back on the dyno and test the results.

Keep in mind we are working on a used engine which has built up gum and varnish deposits throughout. We try to avoid disturbing obvious loose debris that may be present in the valley during cam installation. Some shop towels stuffed in the right places are a good idea and even a vacuum cleaner to grab obvious loose bits before they fall into the sump and into your engine oil. Remember we've disturbed old gaskets and buildup below the intake manifold.

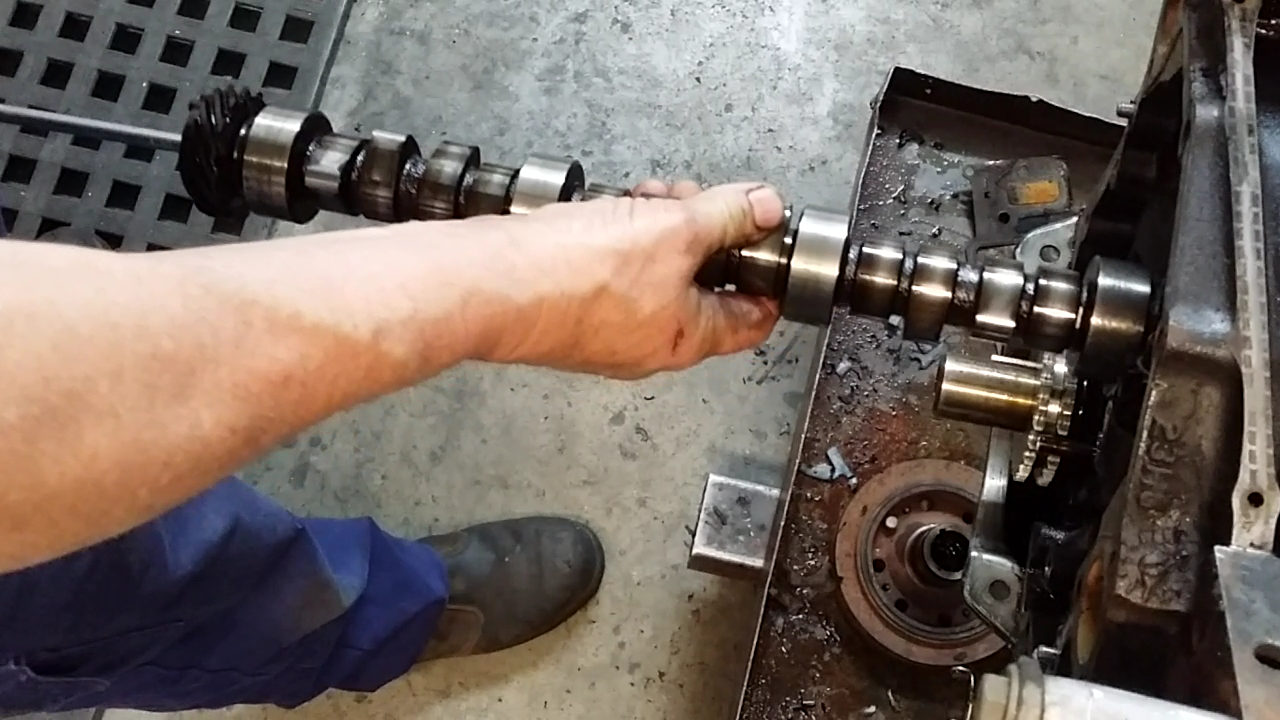

Be careful also in the case of an engine where the cam lobes are severely worn. This often also means lifter bases become mushroomed. As a result forcing them through your blocks lifter bores from above as we are doing here can damage the lifter bores permanently. They must be removed from below with the engine flipped over and the oil pan removed. Our engines cam was still in very good condition as were the lifter bases.

We reused the original pushrods, harmonic balancer and oil pump for our dyno testing. If you inspect these parts and find them to be worn you should replace them. The timing case oil seal should also always be replaced and at least a speedy sleeve installed on the balancer seal surface to prevent premature seal where.