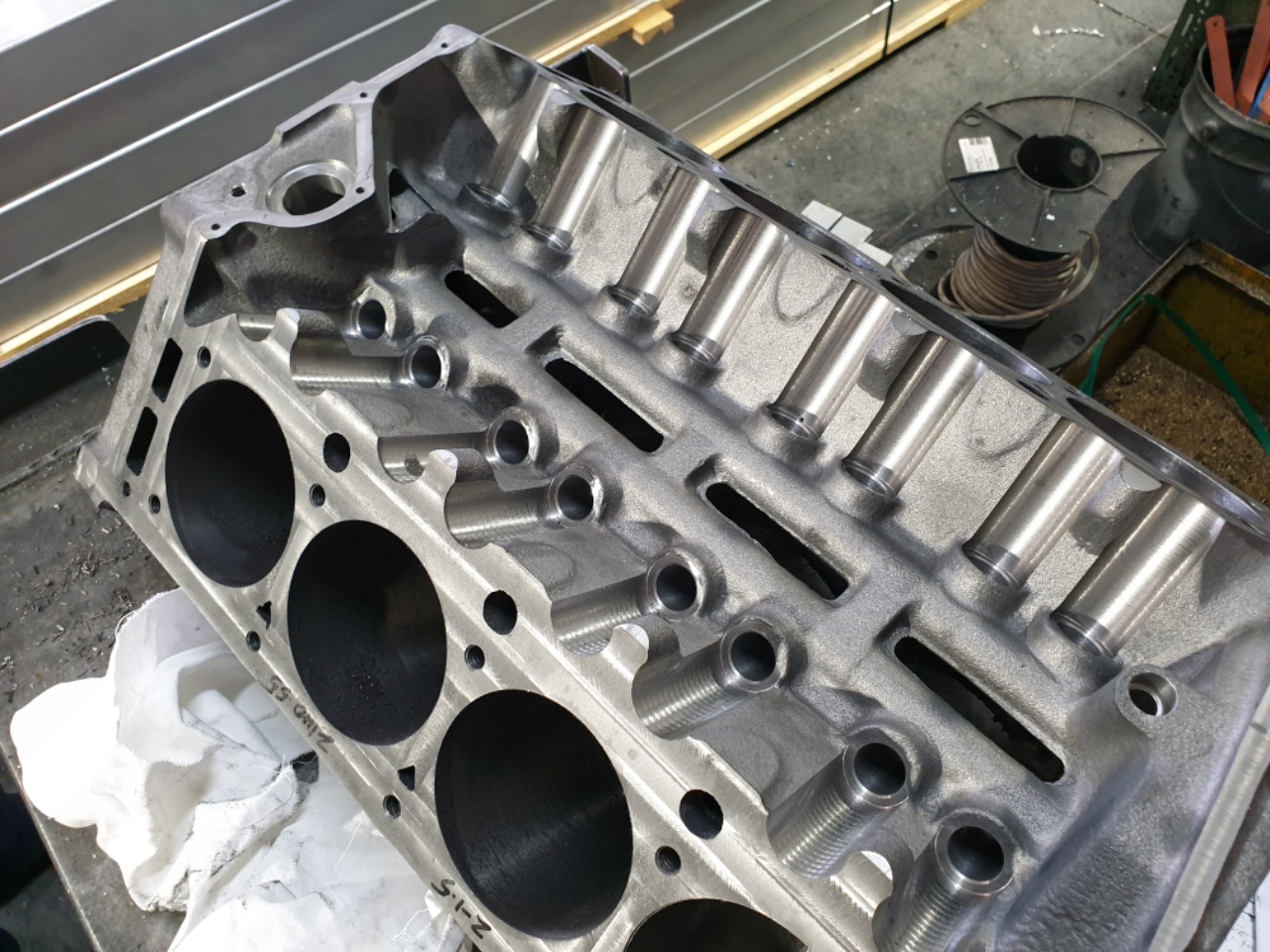

The first casting has come off the CNC machine and the results were wonderful. The casting was flawless. Material is exactly as required, very tough with a very high nickel content providing incredible density and precise machineability.

The siamesed bores allow large bore sizes up to 4.185". The deck surfaces are double the thickness of the original factory block providing immense strength to avoid deck surface deflection even under extreme loads from boost or nitrous oxide. The problem of course with extra strength and material comes extra casting weight so our new block will be up to about 25% heavier than a factory VN-VT block. We haven't weighed the finished casting as it's not fully machined yet.

Regardless, extra weight at a low centre of gravity in a street or race car is a small price to pay for all the benefits the new block will bring to the table. Virtually everyone will be using an aluminium cylinder head on engines built from our block so overall engine weight will most likely be no more than a full cast iron factory engine and most likely still less than the factory engine. This will depend on engine capacity chosen.

Our stepped 4 bolt main caps in the centre three locations will be standard. By virtue of their design they are far better at clamping your crank than splayed caps or any flat cap design made. We will be making steel 2 bolt main front and rear main caps to match the centre three caps. We are working on their final design now.

The oiling system will see main bearings receive oil first and lifter galleys on both banks will be oiled simultaneously as well. We still have several options in how to achieve this but suffice to say, oiling will see needed improvement over the original factory design.

At this stage many people are asking for extra deck height, 1/2" head studs, extra cylinder head fastening bosses incorporated into the casting in the valley area, larger cam bearing bores for custom cam cores, oil restrictor capability and more. Well, to be honest we are beginning the project as a direct OEM replacement with .005" to .010" above stock deck height. All mains and head fastener holes will be drilled to 7/16" factory sizes. Cylinder bores will be finished to a little under 4.00" so customers can choose to go with anything from 4.00" to 4.185" bore sizes. We did add some cast in valley bosses to allow for extra smaller cylinder head fasteners but aside from that the OEM replacement block with significant improvements is our real design brief.

You will be able to use factory style replacement oil pans, timing cases, oil pumps, cylinder heads, intake manifolds, engine mounts, gasket sets, camshafts, lifters, timing chain sets, distributors, crankshafts with factory style rope rear main seal and knurling. You will not need any custom components of this type except for the larger bore versions where specific head gaskets to suit the larger bores will need to be used.

Our second casting will soon be fully machined to 100% completion and an engine will be fully built to test the engine block dynamically in running form. Once this has been successfully completed the blocks will be available for general sale.

We estimate this to be closer to the last few months of 2019.